Current Status of the Japanese Steel Industry

Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

Steelmaking in an electric furnace, which uses reduced scraps, can reduce CO2 emissions, and is said to have the potential to achieve carbon-neutral steelmaking if green electricity can be used for heating. However, that cannot be realized unless a necessary and sufficient amount of scraps can be procured. In addition, scraps are known to contain impurities such as metal elements other than iron which would degrade the characteristics of steel materials.

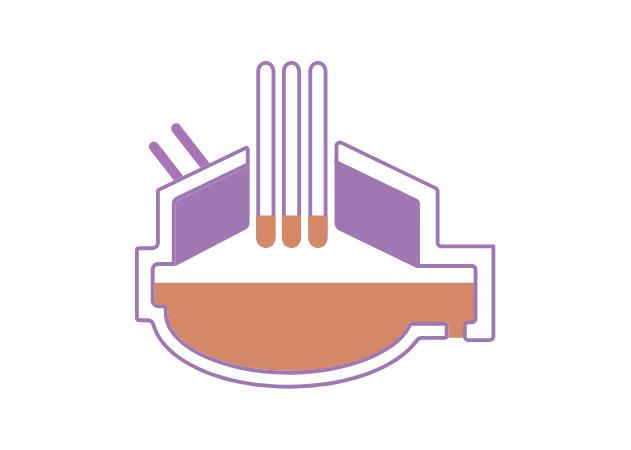

In this project, we will work to develop a technology for manufacturing high-grade steel by melting reduced iron manufactured by a direct reduction process. An electric furnace is less productive than a blast furnace, and in particular, it is said that it takes time to melt reduced iron manufactured by a direct reduction process. In this project, we will study measures to remove impurities (such as phosphorus and nitrogen) and efficient methods for melting reduced iron.

* The years are all planned.

* The years are all planned.

01

01Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

02

02various technological issues to be addressed for realizing steelmaking using hydrogen. We will also address these issues.

03

03In this project, we will study measures to realize carbon-neutral steelmaking that takes advantage not only of the characteristics of blast furnaces but also CCUS technology.

04

04In this project, we will study measures to realize direct reduction ironmaking using hydrogen in a shaft furnace.

05

05In this project, we will work to develop a technology for manufacturing high-grade steel by melting reduced iron manufactured by a direct reduction process.