Current Status of the Japanese Steel Industry

Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

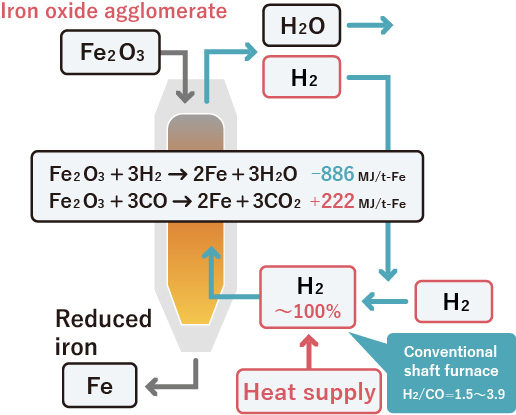

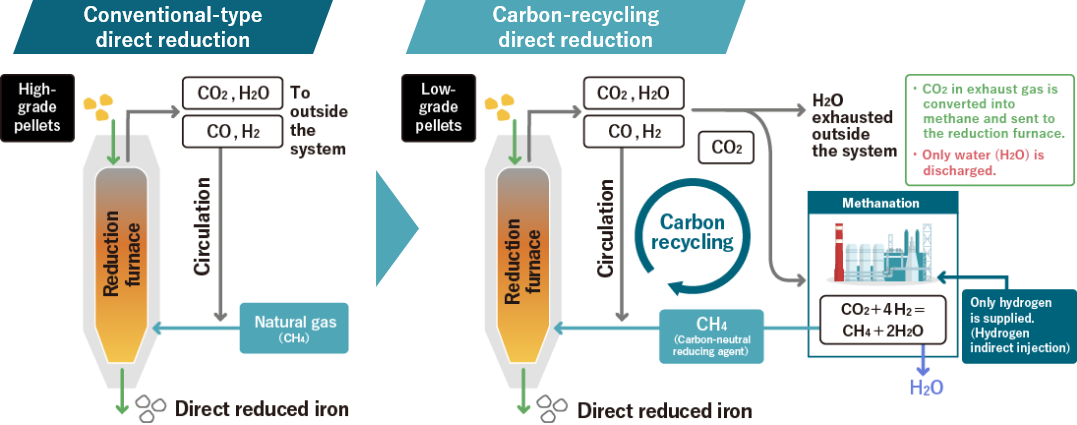

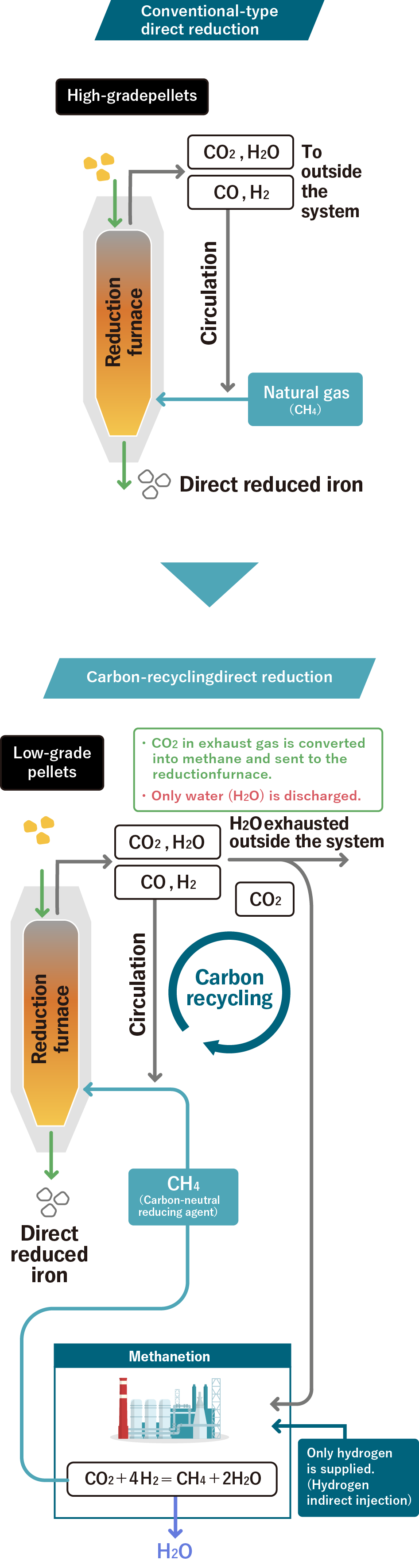

The direct reduction ironmaking process using natural gas is used in Latin America, the Middle East, and other areas where natural gas is inexpensive, and approx. 100 million tons are annually produced worldwide by this process as of 2020. This process uses a gas reducing agent, which is considered to be replaceable with hydrogen. However, iron ore reduction using hydrogen is an endothermic reaction, which poses an issue. Including this, there are many issues to address in using hydrogen in this process.

In this project, we will study measures to realize direct reduction ironmaking using hydrogen in a shaft furnace.

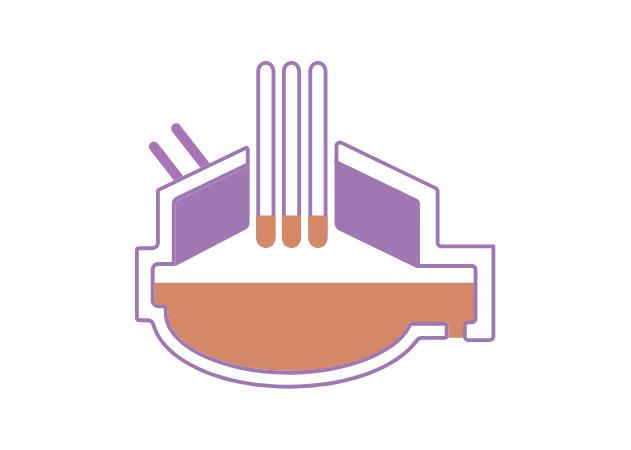

| Conventional shaft furnace | Hydrogen reduction shaft furnace | |

|---|---|---|

| Reducing agent | Natural gas | Hydrogen |

| H2 concentration | 60〜80% | Up to 100% |

| Heat supply | Temperature control of the reducing gas by burning natural gas and exhaust gas | Temperature control of the reducing gas,such as heating of hydrogen by external heat supply and others |

| Raw material | High-grade pellets | Low-grade raw materials |

Tackling the development of technology to reduce iron oxide only with hydrogen

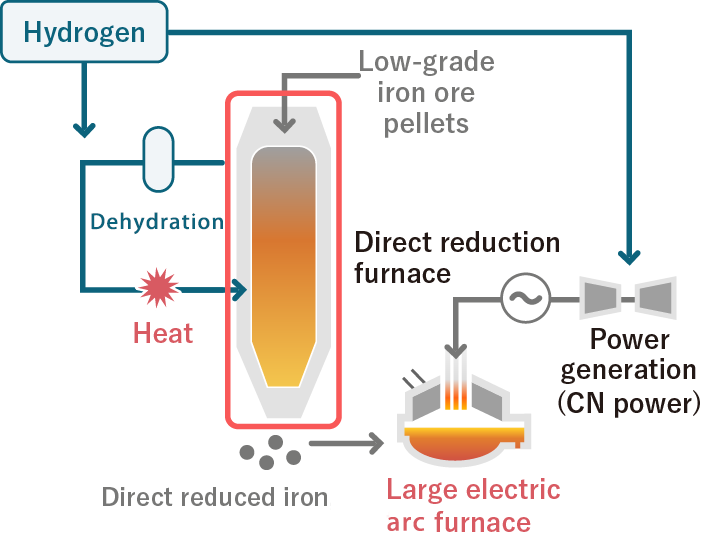

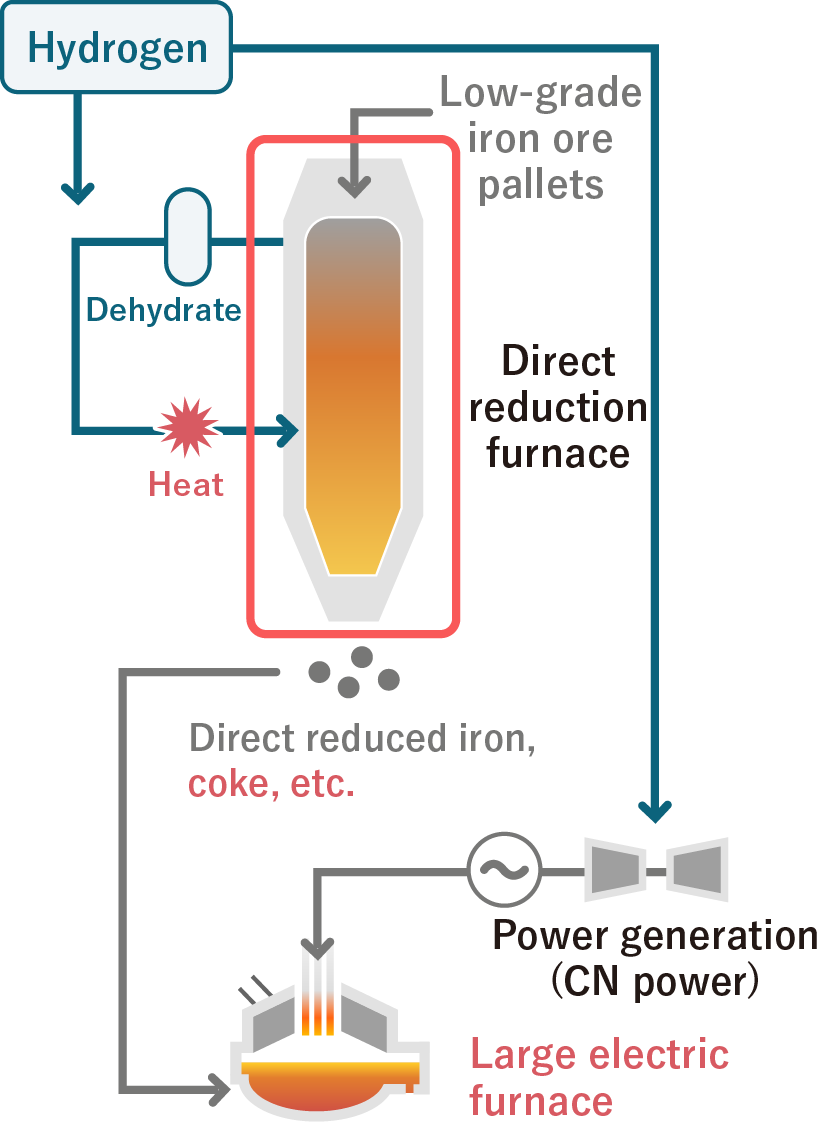

Establishing the steelmaking technology integrating a shaft furnace, featuring the hydrogen reduction process capable of using low-grade ore, with an electric arc furnace

⇒Ensuring competitiveness with more flexible use of resources

A small-scale test shaft furnace (1 t/hr) will be constructed and a test will be started in 2025 at the Hasaki Research and Development Center of Nippon Steel.

An idea of the hydrogen reduction shaft furnace

Flexible capability of using different grades of iron source that conventional shaft furnaces lack: aiming at using low-grade raw materials

01

01Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

02

02various technological issues to be addressed for realizing steelmaking using hydrogen. We will also address these issues.

03

03In this project, we will study measures to realize carbon-neutral steelmaking that takes advantage not only of the characteristics of blast furnaces but also CCUS technology.

04

04In this project, we will study measures to realize direct reduction ironmaking using hydrogen in a shaft furnace.

05

05In this project, we will work to develop a technology for manufacturing high-grade steel by melting reduced iron manufactured by a direct reduction process.