Current Status of the Japanese Steel Industry

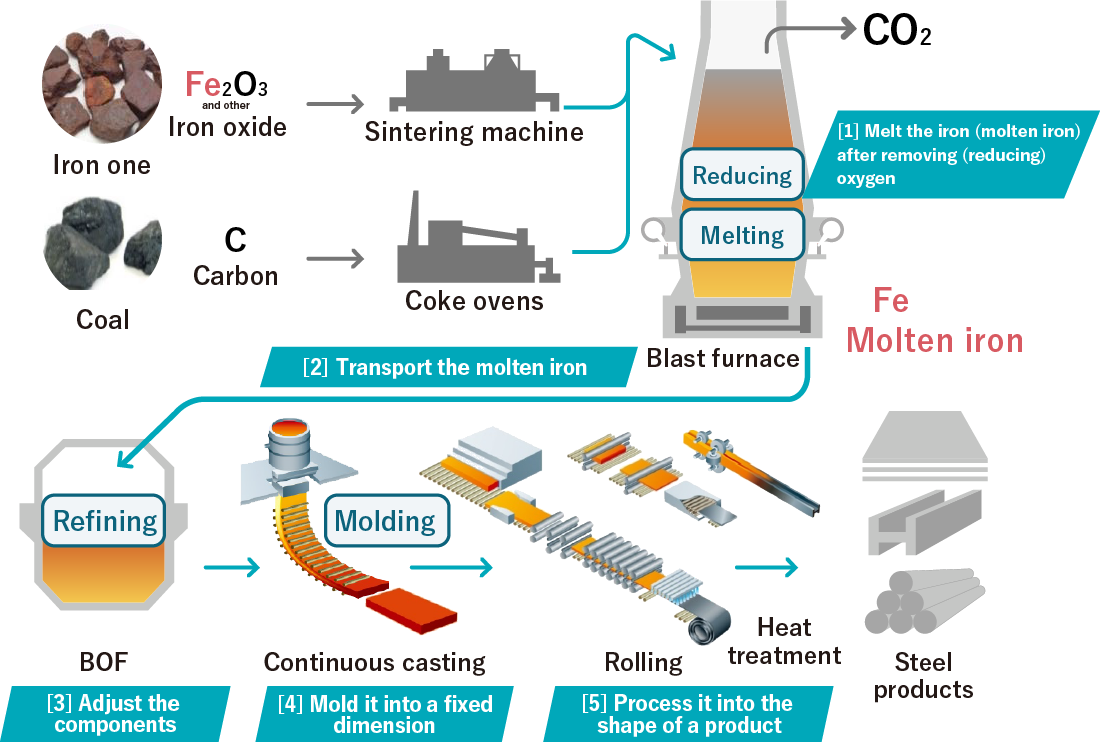

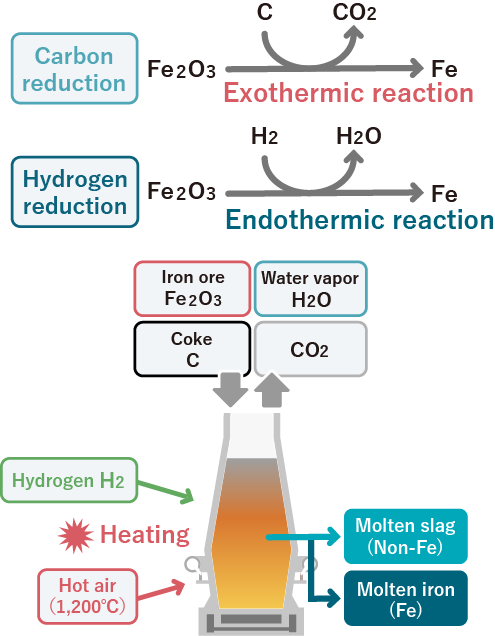

Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

In the future, we need to further reduce CO2 on a global scale, and technology development is key to meeting this need. In the long term, it will be essential to take drastic measures enabled by innovative technologies.

On the other hand, there are various technological issues to be addressed for realizing steelmaking using hydrogen. We will also address these issues.

(Source) Nippon Steel Carbon Neutral Vision 2050

https://www.nipponsteel.com/ir/library/pdf/20210330_ZC.pdf

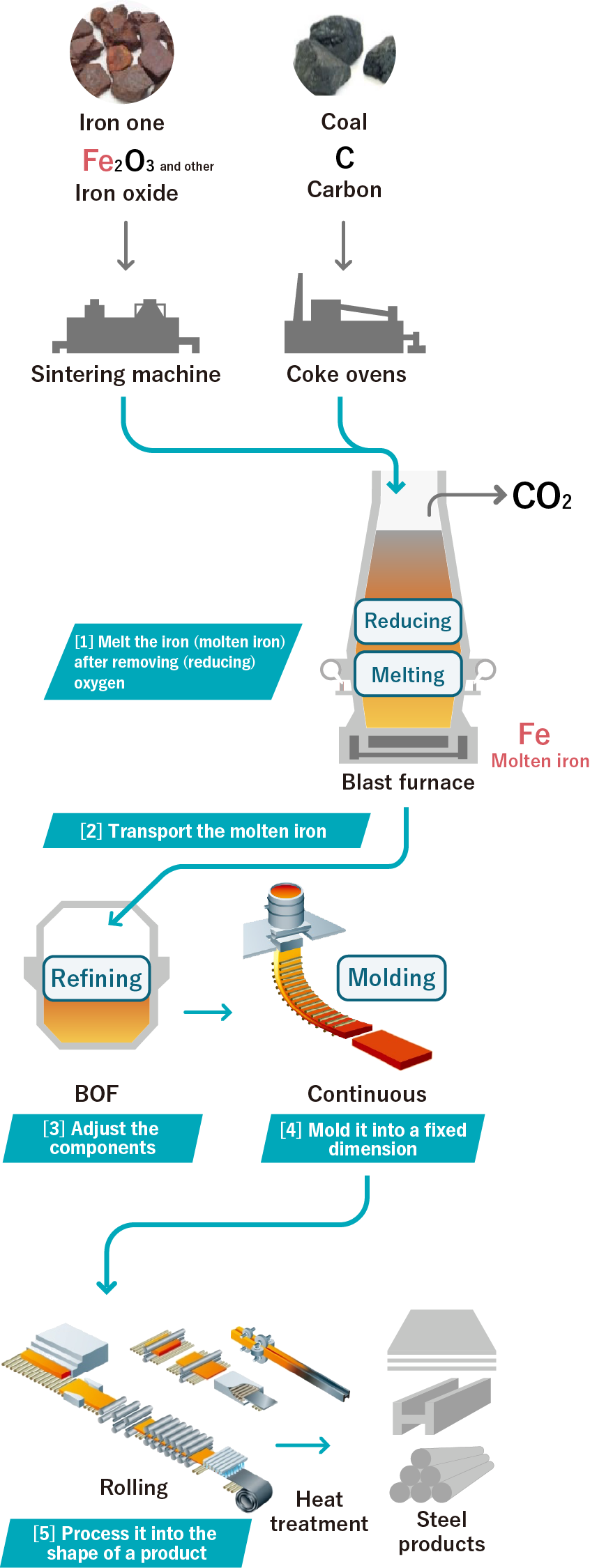

Breakdown of CO2 emissions from the steelmaking process (t-CO2/t-crude steel)

(Source) Revised from “Carbon Trust, International Carbon Flows—Steel (2011)”

Issue

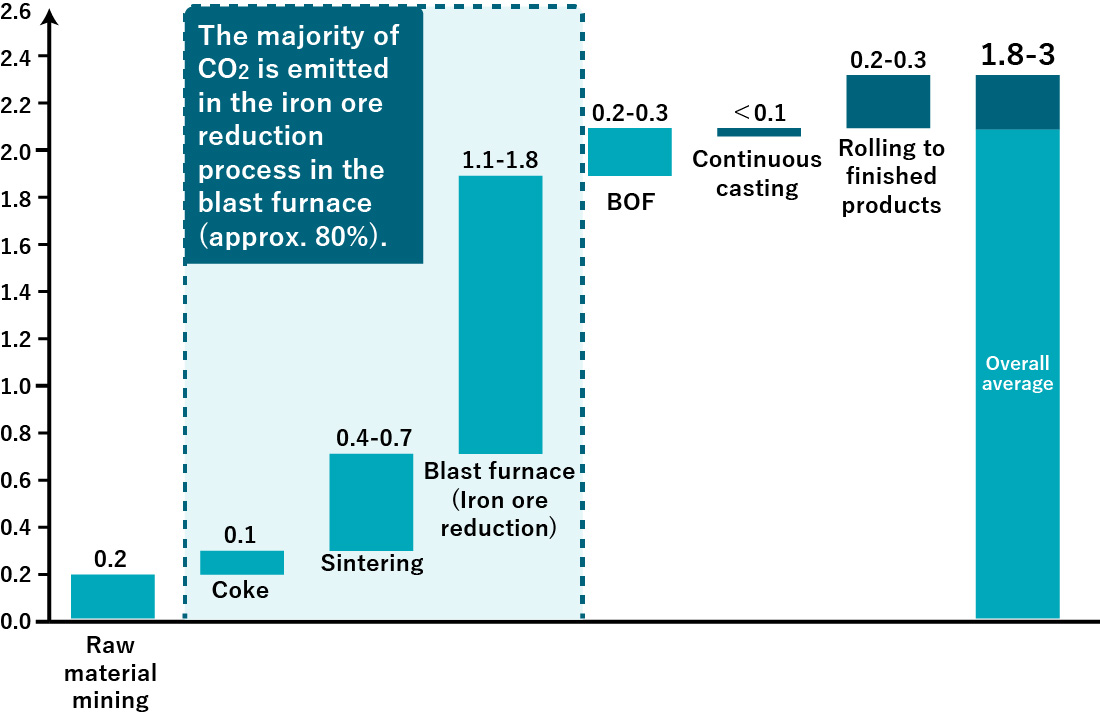

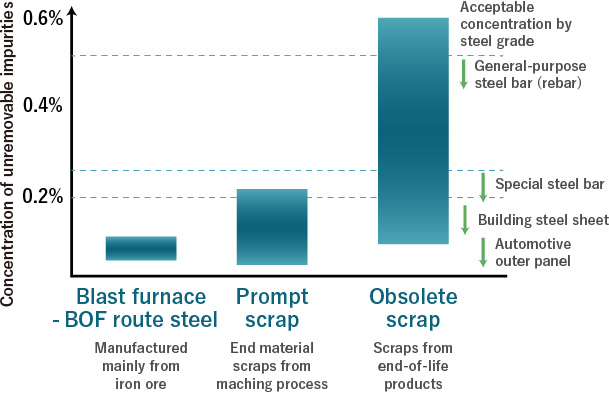

Carbon reduction is an exothermic reaction, while hydrogen reduction is an endothermic reaction and causes the temperature to drop. Hydrogen must be heated to increase the rate of hydrogen reduction.

| Conventional blast furnace | Hydrogen blast furnace and shaft furnace | |

|---|---|---|

| Heated gas (Risk of explosion) |

Air (No risk) |

Hydrogen (Carries risk) |

| Blast volume | Thousands of Nm3/min | A massive amount of heated hydrogen needs to be injected in addition to the one on the left. |

| Heating method | Hot stove (Heat exchange with directly heated firebricks) |

Development of new technology, such as indirect heating, is required to ensure safety (Heating efficiency needs to be addressed.) |

Technology to handle endothermic reactions is required

(Source) Nippon Steel Carbon Neutral Vision 2050 and others

https://www.nipponsteel.com/ir/library/pdf/20210330_ZC.pdf

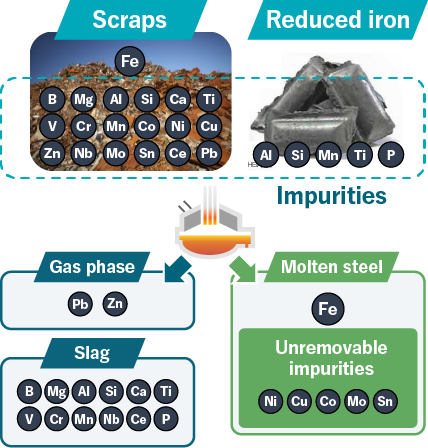

Revised from the “23rd research presentation of the Japan Society of Material Cycles and Waste Management (2012) 23_269” by Takehito Hiraki, et al.

Revised from the “Assessment of the Impact of Rising Levels of Residuals in Scraps, Proceedings of the Iron & Steel Technology Conference (2019)” by Jones, A.J.T.

Manufacturing high-grade steel in the EAF process by establishing the technology to make entrapped elements that are harmful to material quality harmless

(Source) Nippon Steel Carbon Neutral Vision 2050 and others

https://www.nipponsteel.com/ir/library/pdf/20210330_ZC.pdf

| Advantages |

|

|

|

|---|---|---|---|

| Problems |

|

|

|

(Source) JFE Group Environmental Management Vision 2050

https://www.jfe-holdings.co.jp/investor/zaimu/g-data/jfe/2020/2020-environmental-management-vision210525-01.pdf

01

01Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

02

02various technological issues to be addressed for realizing steelmaking using hydrogen. We will also address these issues.

03

03In this project, we will study measures to realize carbon-neutral steelmaking that takes advantage not only of the characteristics of blast furnaces but also CCUS technology.

04

04In this project, we will study measures to realize direct reduction ironmaking using hydrogen in a shaft furnace.

05

05In this project, we will work to develop a technology for manufacturing high-grade steel by melting reduced iron manufactured by a direct reduction process.