Current Status of the Japanese Steel Industry

Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

The Japanese steel industry has contributed to reducing CO2 as a countermeasure against global warming by achieving the world’s highest level of energy efficiency in production processes through constant efforts to save energy, supplying lightweight, high-strength, and highly functional steel materials, and promoting energy-saving technologies developed in Japan overseas. Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

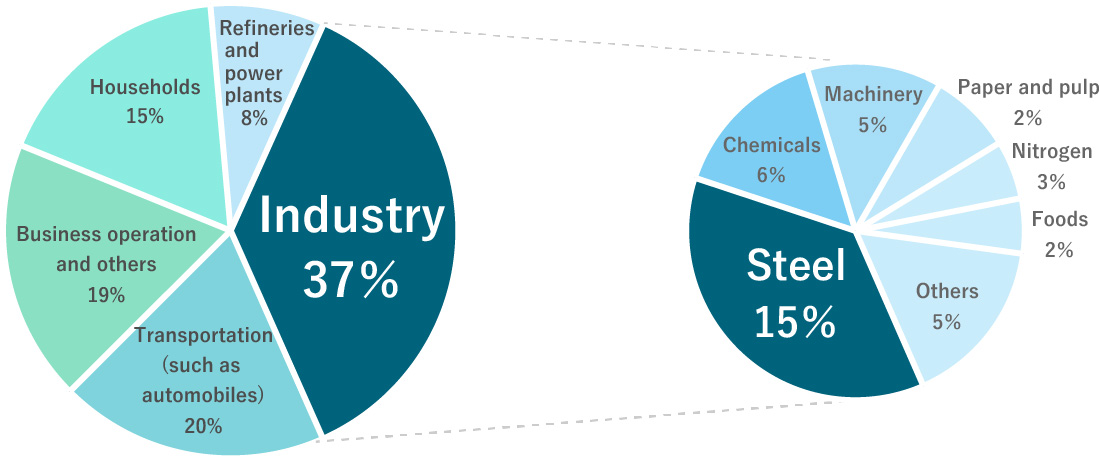

The figures were calculated after allocating the emissions caused by electric utilities generating power for final demand sectors according to power consumption. Machinery includes the metal product manufacturing industry, and chemical industry includes the production of petroleum and coal products.

The charts were created based on the “Data of Greenhouse Gas Emissions in Japan (FY1990–2020) (Final Figures)” released by the Ministry of the Environment.

http://www-gio.nies.go.jp/index-j.html

What is ethical consumption?

Goal 12 of Sustainable Development Goals (SDGs) is “Responsible consumption and production.”

The 17 international goals set in the UN General Assembly in September 2015 include “securing sustainable consumption and production patterns” in addition to poverty, hunger, energy, climate change and peaceful society.

(Source) Consumer Affairs Agency: “Survey on the awareness of ethical consumption in August 2020” and others

Higher awareness among consumers regarding ethical consumption

Everyone should take actions as much as possible for problems such as natural disasters, environmental destruction, and resource depletion.

57.1%

It is acceptable for prices to increase when purchasing ethical products and services.

69.0%

Demand for CO2 reduction from users

(Source) Consumer Affairs Agency: https://www.ethical.caa.go.jp/ethical-consumption.html

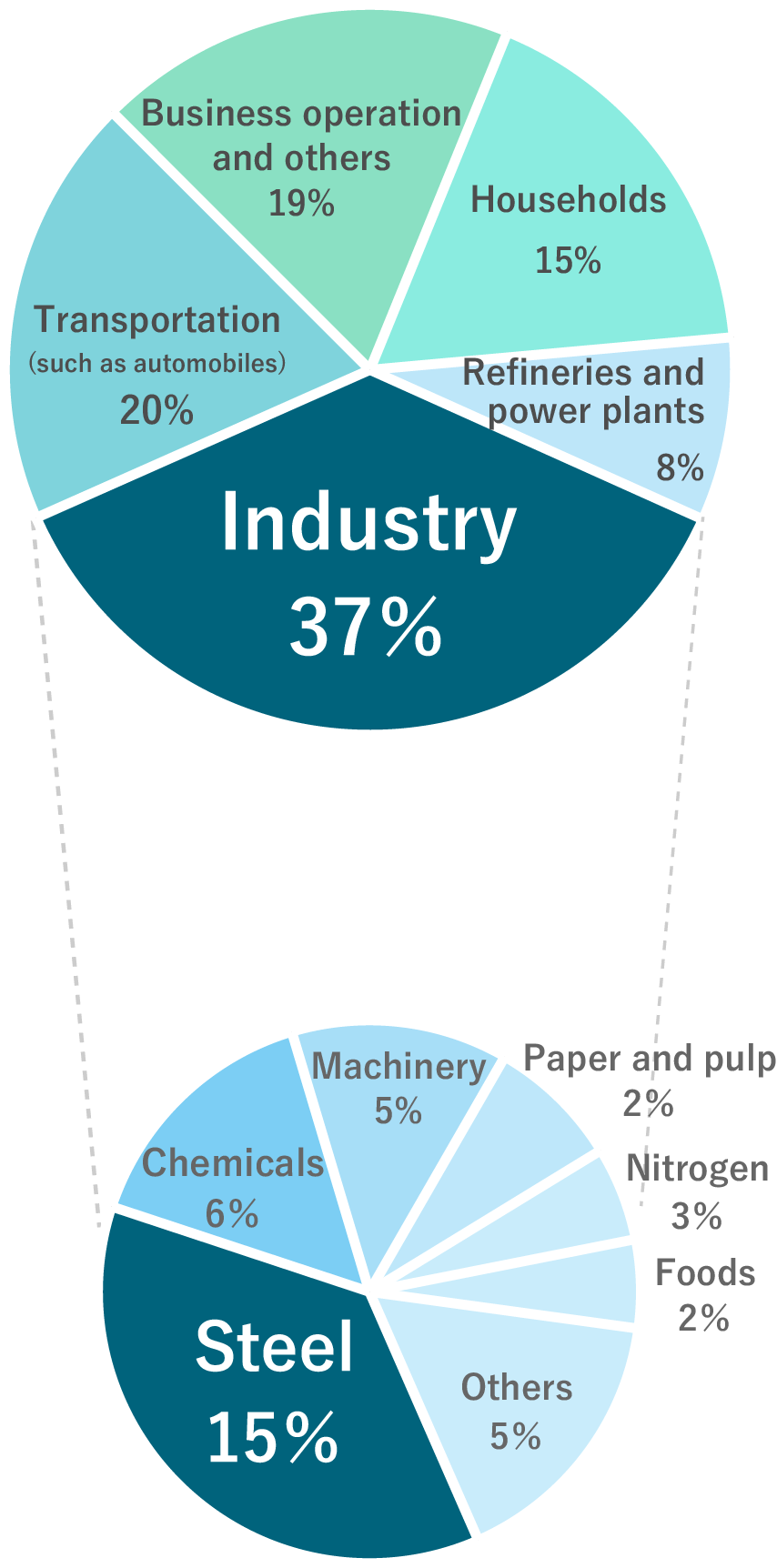

CO2 Reduction Target of the Japanese Steel Industry for 2030

CO2 emissions from energy compared to FY2013:

Reduction by 30%

(approx. 57.9 million tons)

This shall be met on the assumption that requirements are fulfilled that are necessary to meet macro assumptions in the Japanese Government’s Energy Basic Plan and to take various measures (such as promoting energy conservation by introducing BAT, etc.; utilizing waste plastic; introducing innovative technology that is now being developed and will be available in around 2030; and utilizing raw materials and fuels that contributes to CO2 reduction).

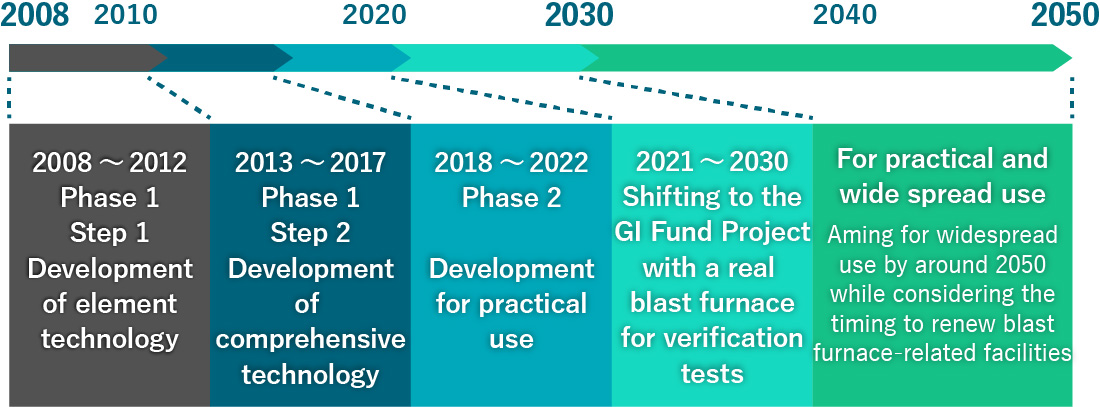

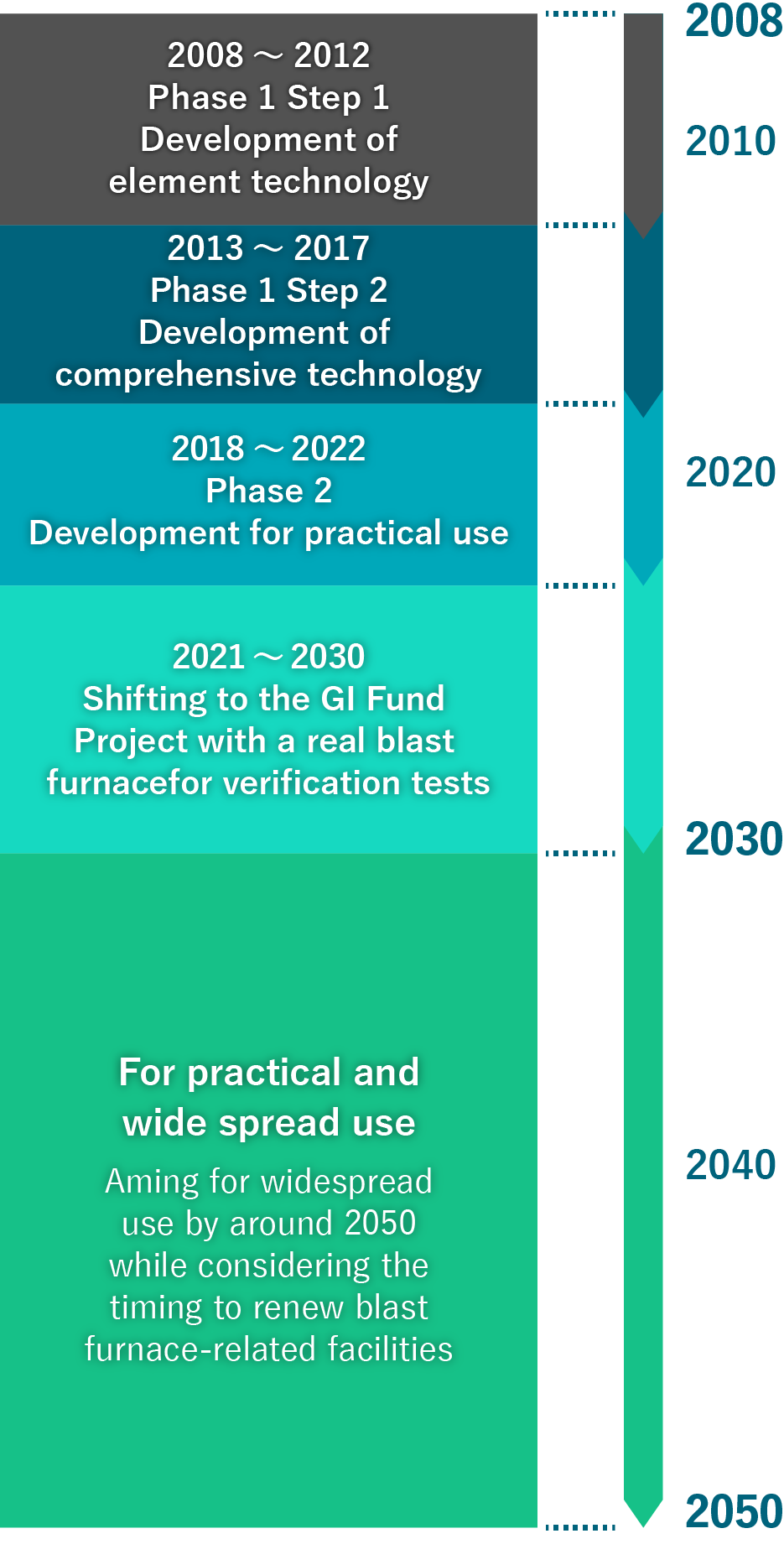

Carbon-neutral Action Plan of the Japanese Steel Industry

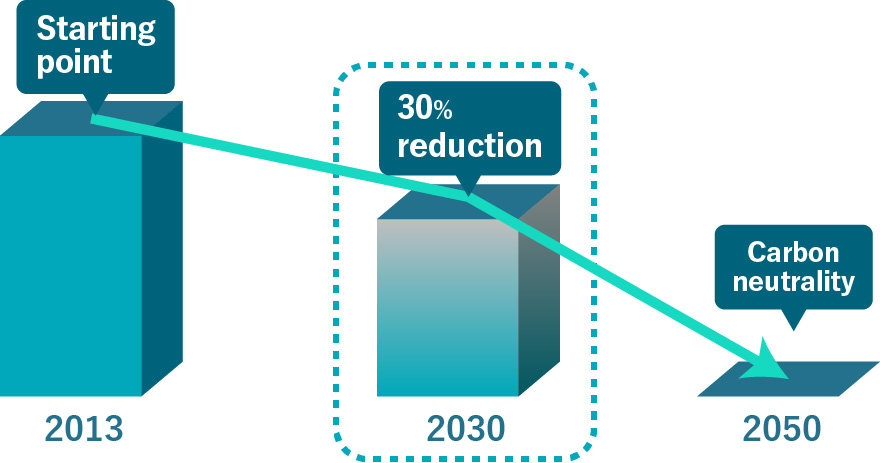

COURSE 50 test blast furnace

NEDO & The Japan Iron and Steel Federation: COURSE 50

COURSE 50 CO2 capture and separation facility

NEDO & The Japan Iron and Steel Federation: COURSE 50

Cost increase for realizing carbon-neutral steelmaking

Social collaboration for realizing carbon-neutral steelmaking

01

01Previous efforts to reduce CO2 in production processes and issues we are currently facing are explained here.

02

02various technological issues to be addressed for realizing steelmaking using hydrogen. We will also address these issues.

03

03In this project, we will study measures to realize carbon-neutral steelmaking that takes advantage not only of the characteristics of blast furnaces but also CCUS technology.

04

04In this project, we will study measures to realize direct reduction ironmaking using hydrogen in a shaft furnace.

05

05In this project, we will work to develop a technology for manufacturing high-grade steel by melting reduced iron manufactured by a direct reduction process.